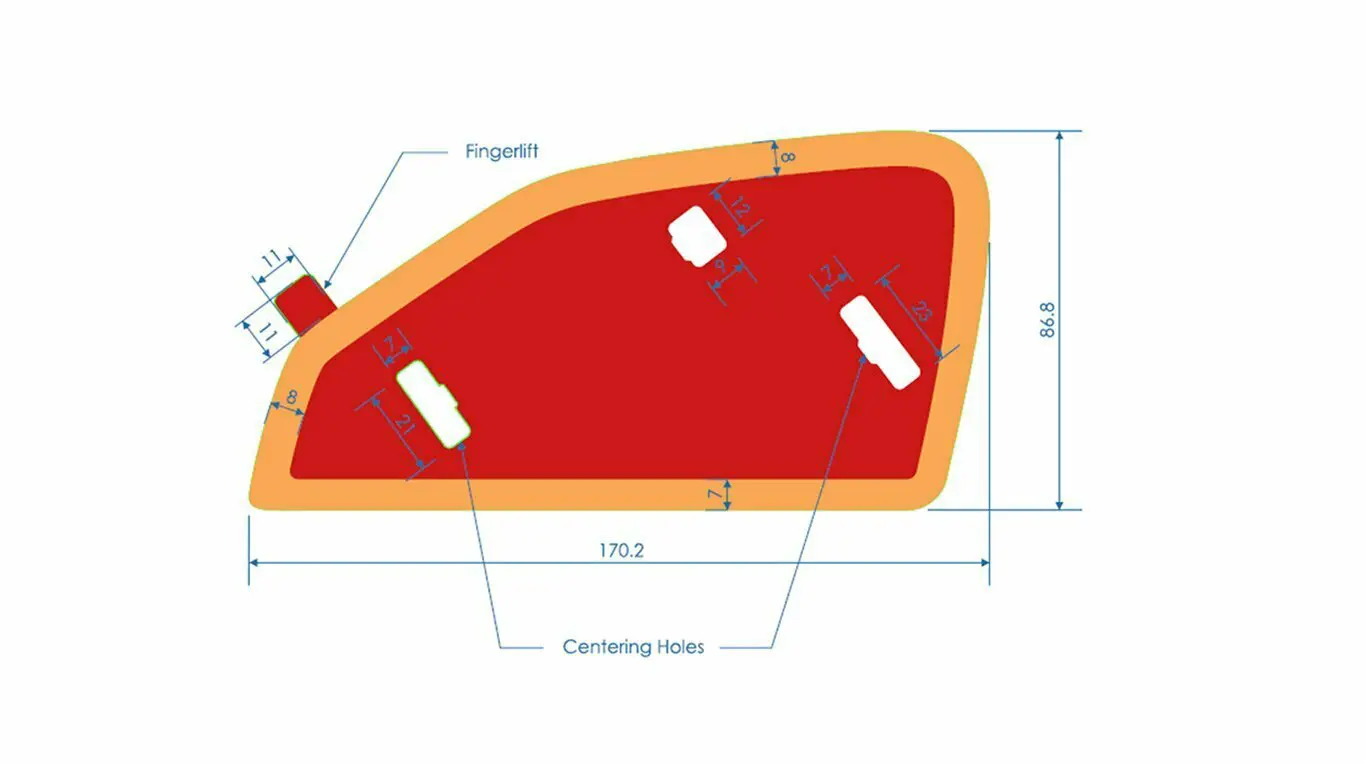

Side car body fascia – Automotive

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part for assembly of a side fascia, at the exterior of the car body.

The issue / challenge submitted to us for settlement, by the client:

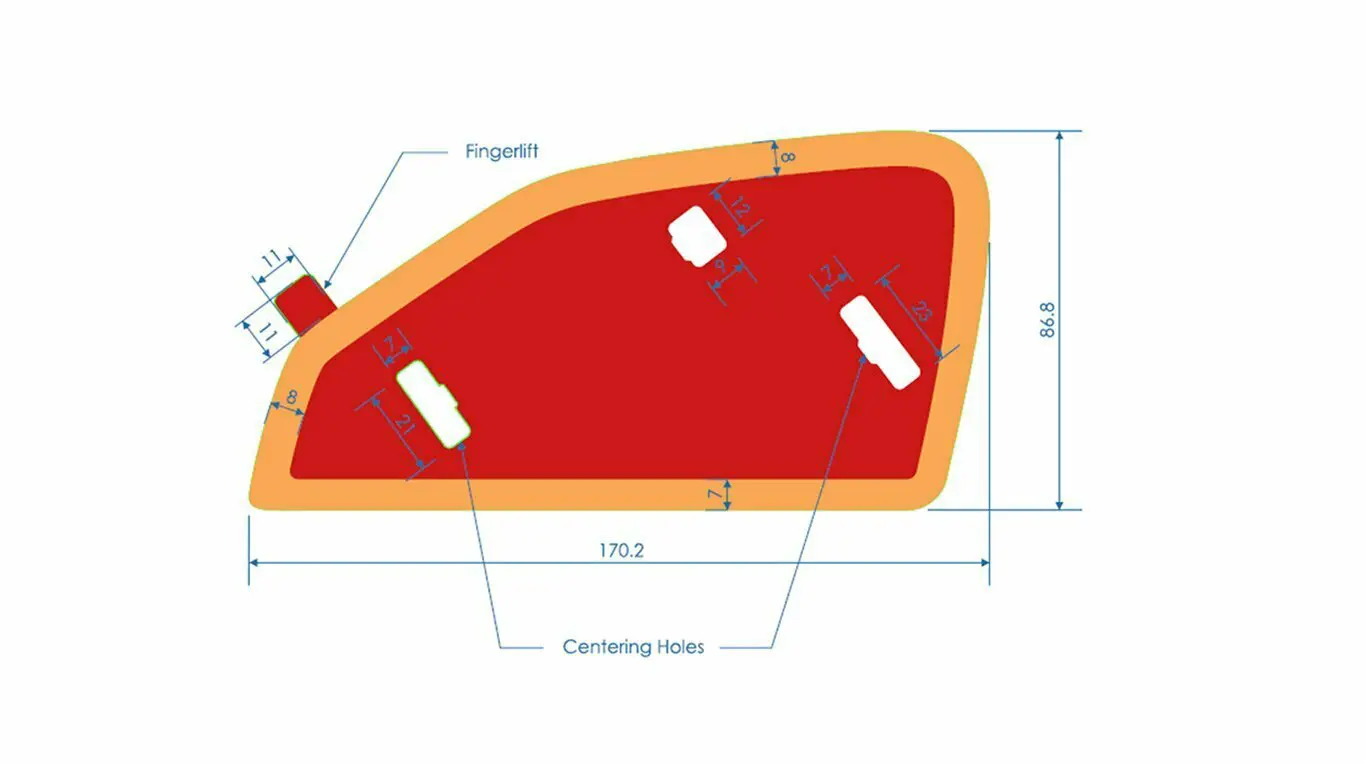

A solution for the supply of a double-sided tape part, for assembly of the reverse camera protection bracket on the tailgate strap.

The tape’s purpose is to bond and seal the camera’s protective case.

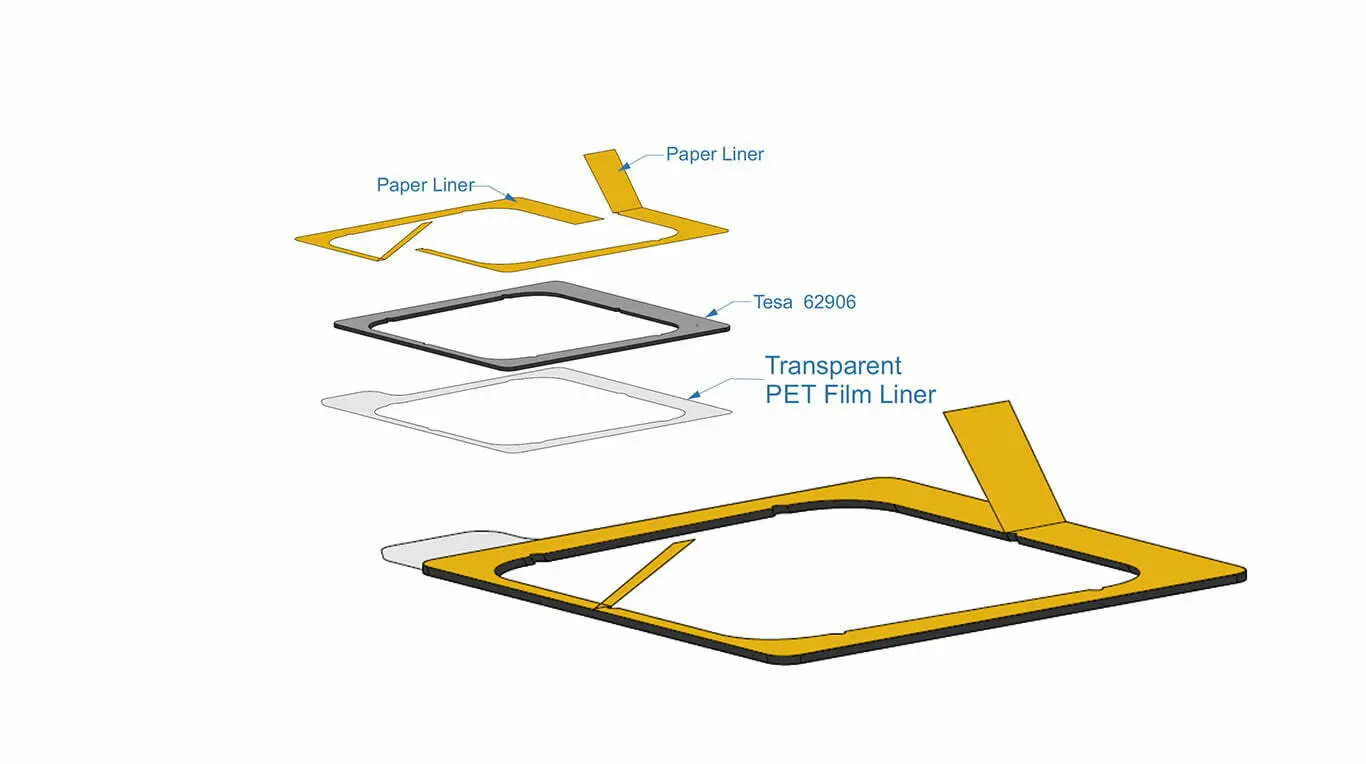

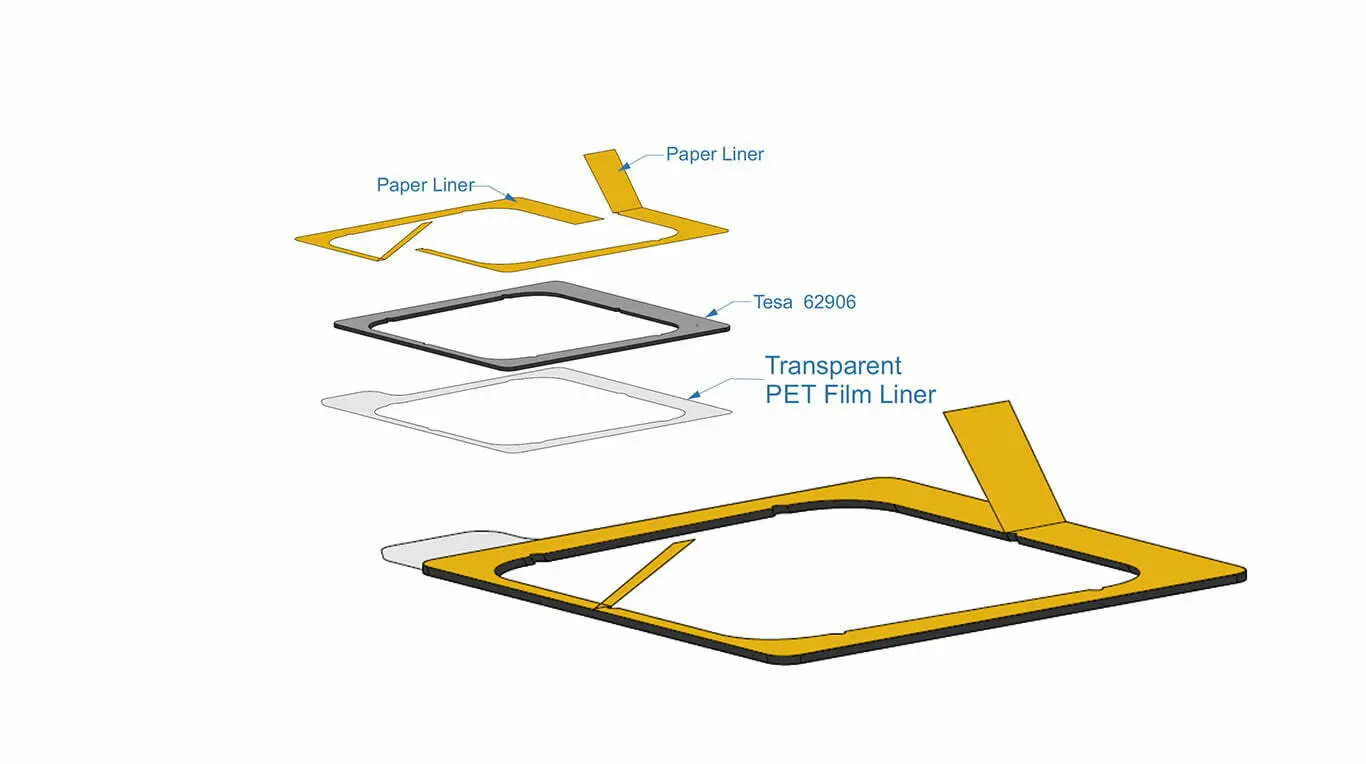

The solutions proposed by us:

MDE Converting suggested the complete cutting of the part, using a ruling assembly providing dimensional stability and ease of application, considering the fine details and the reduced width of the adhesive tape.

The innovation of MDE Converting: The PET support liner, for stability and superposed liners, for application ease and accuracy.

Efficiency for the customer (time-saving, money-saving, high efficiency, dealing with a technical issue)

The proposed and validated definition settled the potential issues for assembly and alignment of the adhesive tape on the support material.

Based on the proposed solution, the customer has improved their cycle times for the process of applying the double-sided tape inlay.

The scrap rate of the process for assembly of the adhesive tape part was minimised.

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part for assembly of a side fascia, at the exterior of the car body.

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part, for assembly of the reverse camera protection bracket on the tailgate strap.

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part and services for the assembly thereof on the plastic part. Very tight tolerance on alignment of the adhesive tape part on the plastic part…