Side car body fascia – Automotive

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part for assembly of a side fascia, at the exterior of the car body.

The issue / challenge submitted to us for settlement, by the client:

A solution for the supply of a double-sided tape part for assembly of a side fascia, at the exterior of the car body.

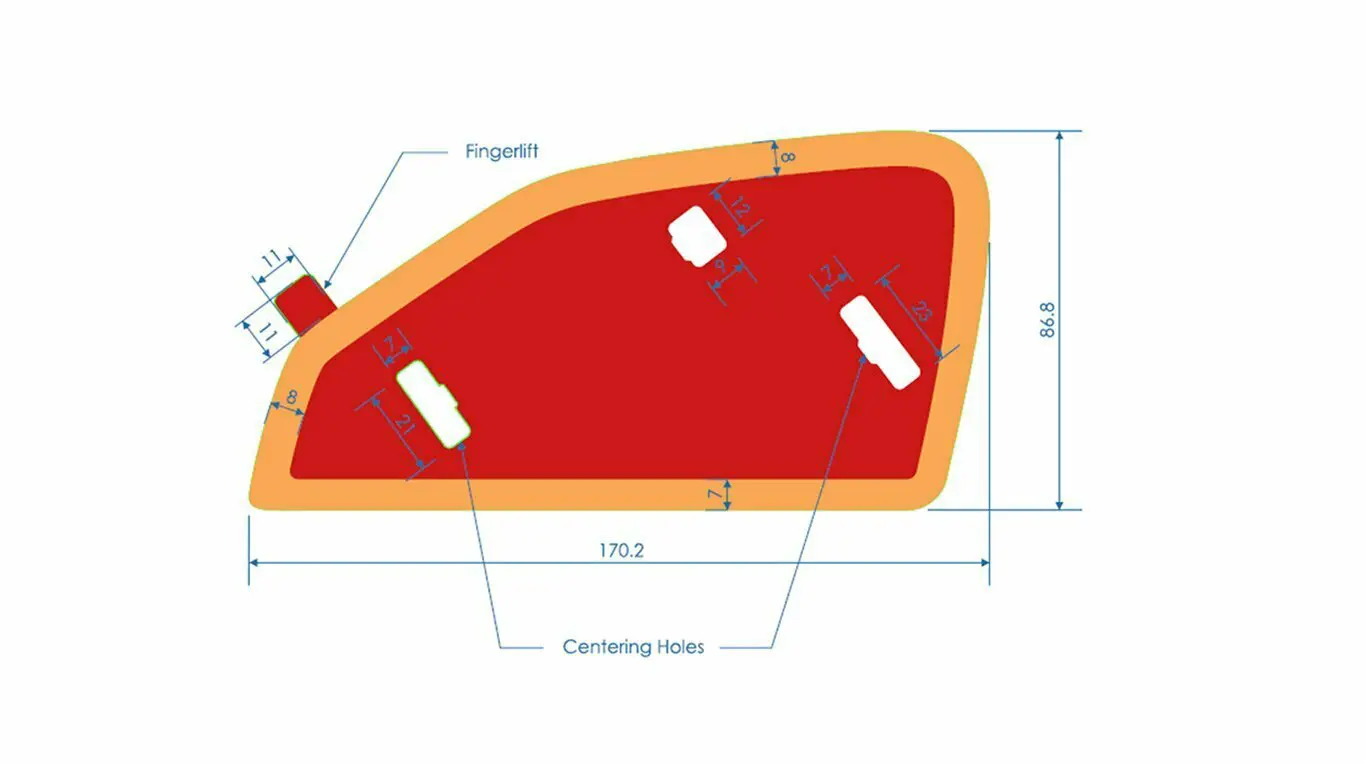

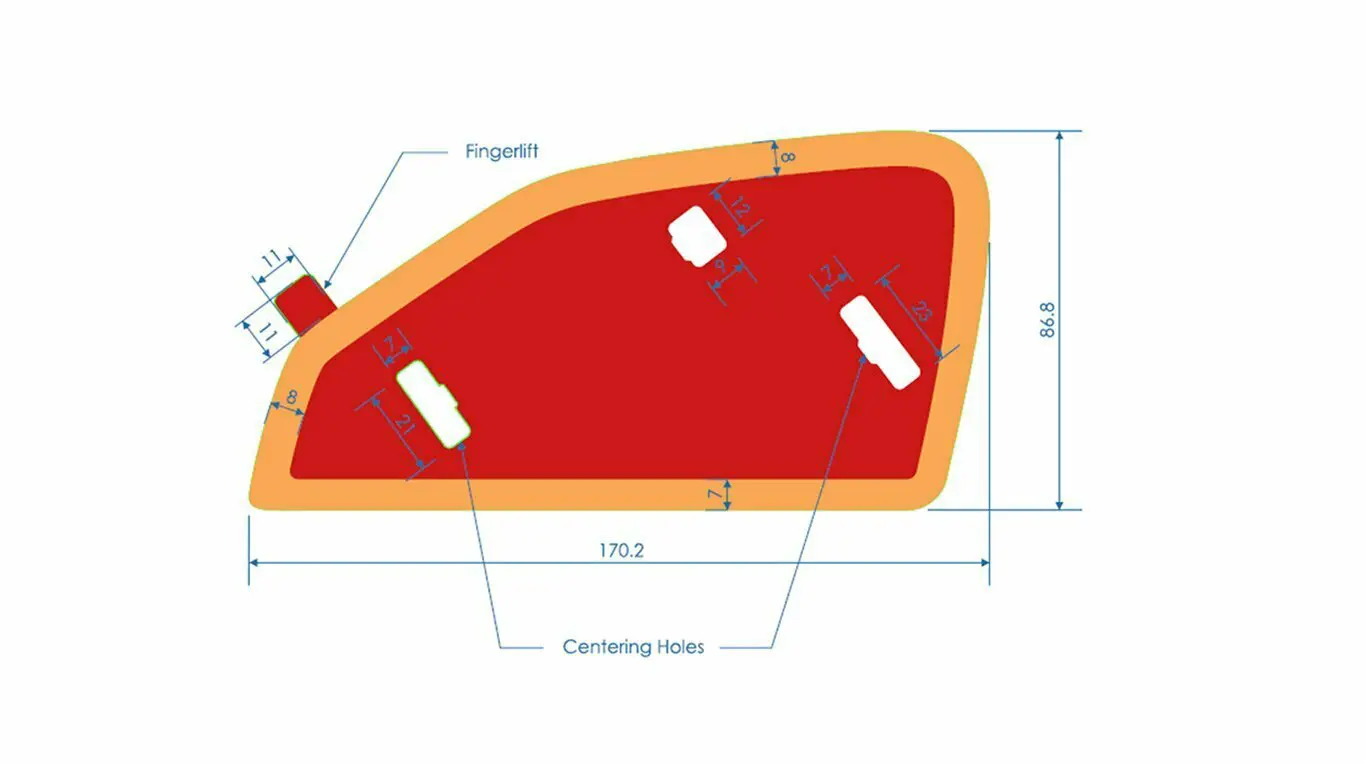

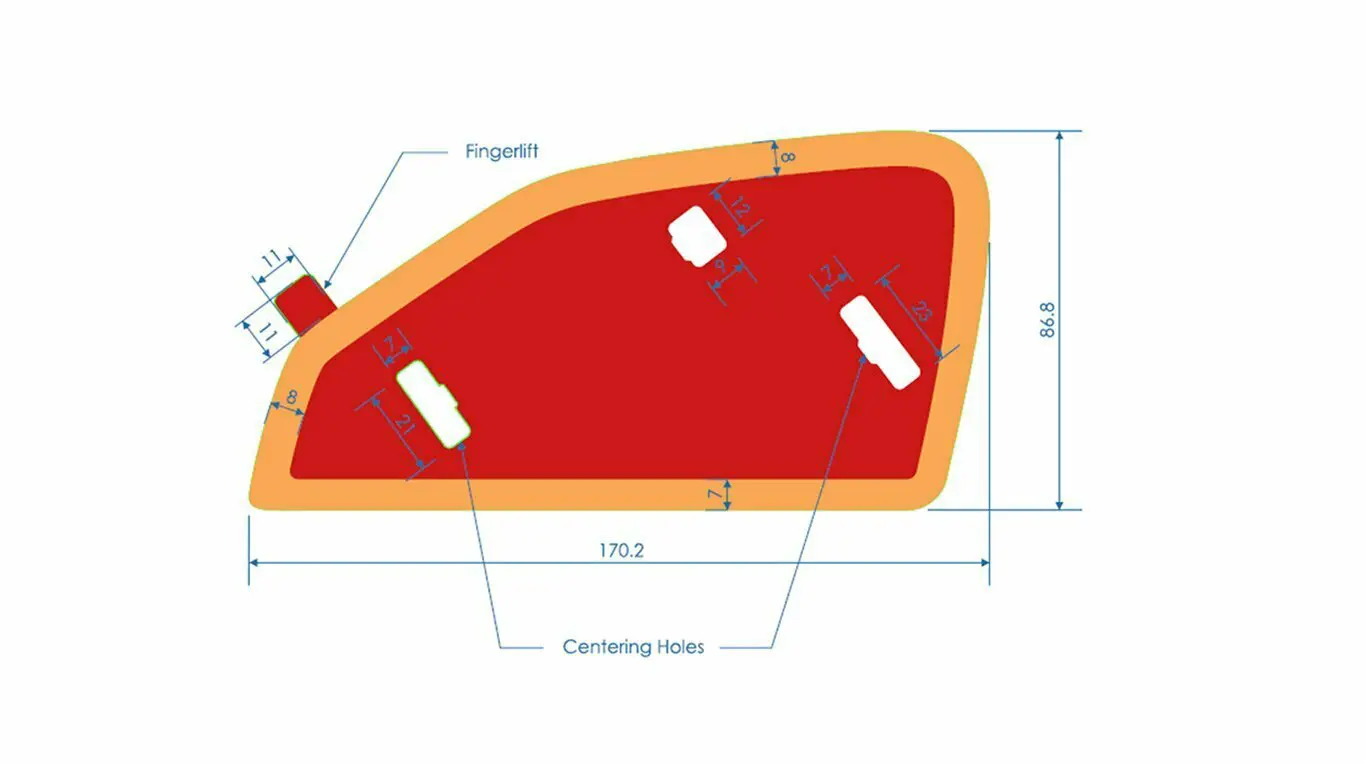

The customer’s suggestion was to carry out the assembly using 3 adhesive tape parts on each plastic component.

The solutions proposed by us:

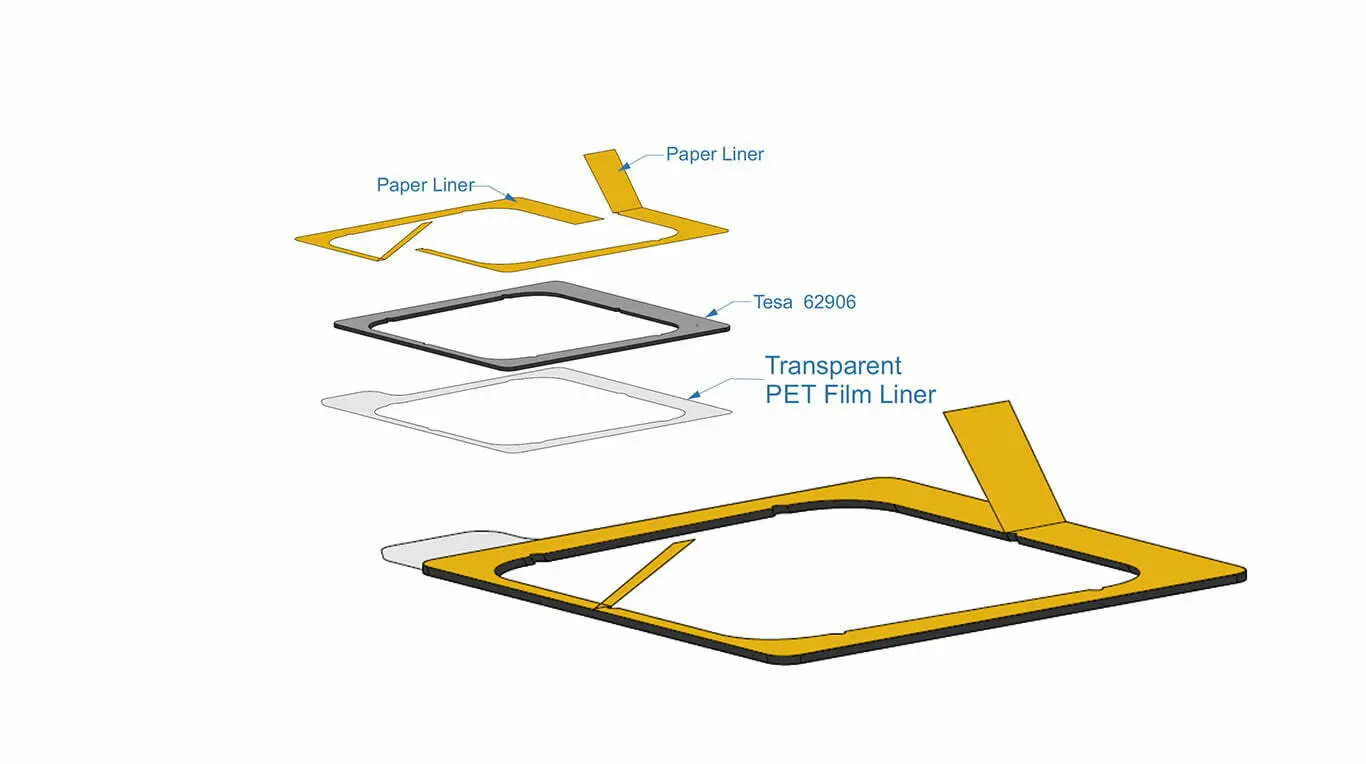

MDE Converting proposed the replacement of the 3 double-sided tapes with full frame individually-cut parts.

The innovation of MDE Converting: The support liner is providing with guiding holes, for application ease and accuracy.

Efficiency for the customer (time-saving, money-saving, high efficiency, dealing with a technical issue)

The full frame definition settled the issue of alignment of the 3 adhesive tape parts, as initially proposed by the customer.

Based on the proposed solution, the customer has improved their cycle times for the process of applying the double-sided tape inlay.

The full frame format provides an even appearance, compared to the initial definition, which minimizes the risk of potential quality issues of our customer, such issues originating from the OEM, in relation to the appearance of the blending of the body and fascia.

Scrap rate minimised.

Forecasted parts volume:

– 100k sets (LH & RH)

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part for assembly of a side fascia, at the exterior of the car body.

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part, for assembly of the reverse camera protection bracket on the tailgate strap.

The issue / challenge submitted to us for settlement, by the client: A solution for the supply of a double-sided tape part and services for the assembly thereof on the plastic part. Very tight tolerance on alignment of the adhesive tape part on the plastic part…